At Finexpolymers, we specialize in manufacturing high-quality spare parts for twin-screw extrusion machines. With our extensive experience and cutting-edge technology, we provide reliable and durable components that ensure optimal performance and longevity of your extrusion equipment.

Manufacturing Twin-Screw Extrusion Spare Parts Service

Key Services Offered

1. Custom Spare Parts Manufacturing:

-

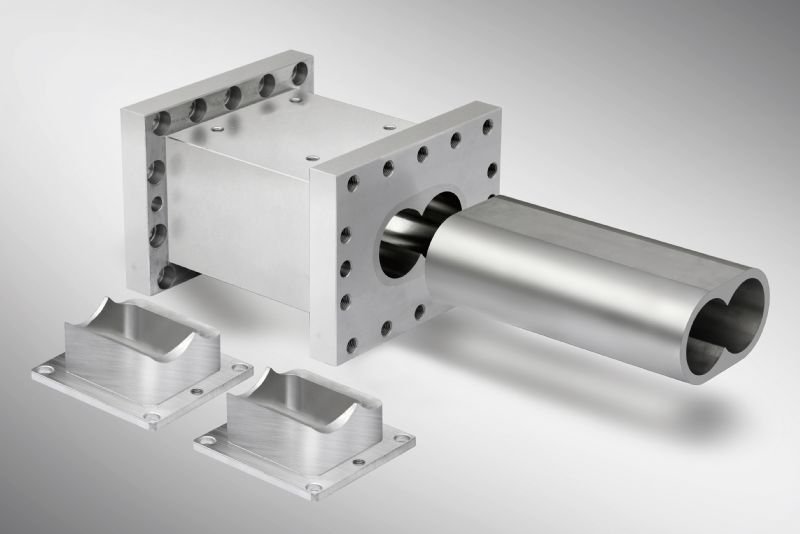

- Screws and Barrels: Precision-engineered screws and barrels tailored to specific extrusion requirements, ensuring efficient mixing, conveying, and plasticizing.

- Kneading Blocks and Discs: Customizable kneading elements designed to optimize shear and mixing in the extrusion process.

- Gearboxes and Bearings: High-quality gearboxes and bearings to maintain smooth operation and extend the life of your extrusion machinery.

2. Material Selection:

-

- Wear-Resistant Alloys: Components made from advanced wear-resistant materials to withstand high-stress conditions and abrasive environments.

- Corrosion-Resistant Materials: Parts constructed from corrosion-resistant alloys to ensure durability in chemically aggressive processes.

3. Precision Machining and Finishing:

-

- Advanced Machining Techniques: Utilizing CNC machining and other advanced manufacturing methods to achieve precise dimensions and tolerances.

- Surface Treatments: Various surface treatments, including nitriding and coating, to enhance the wear resistance and performance of parts.

4. Quality Assurance:

-

- Rigorous Testing: Comprehensive testing and quality control measures to ensure that all spare parts meet the highest standards of performance and reliability.

- ISO Certification: Adherence to ISO standards and best practices in manufacturing to guarantee quality and consistency.

5. Technical Support and Consultation:

-

- Expert Consultation: Technical support and consultation services to help you select the right components and optimize your extrusion process.

- Installation and Maintenance Guidance: Assistance with the installation and maintenance of spare parts to ensure seamless integration and sustained performance.

Benefits of Our Twin-Screw Extrusion Spare Parts Service

1. Enhanced Performance:

-

- Optimized Efficiency: Precision-engineered parts improve the overall efficiency and productivity of your twin-screw extrusion machines.

- Extended Equipment Life: High-quality materials and manufacturing processes ensure long-lasting durability, reducing the need for frequent replacements.

2. Cost Efficiency:

-

- Reduced Downtime: Reliable spare parts minimize equipment downtime, maintaining continuous operation and productivity.

- Lower Maintenance Costs: Durable components decrease the frequency and cost of maintenance, providing long-term savings.

3. Customization and Flexibility:

-

- Tailored Solutions: Custom spare parts designed to meet your specific extrusion needs, enhancing the versatility and adaptability of your machinery.

- Quick Turnaround: Efficient manufacturing processes and quick turnaround times ensure you receive the parts you need when you need them.

4. Comprehensive Support:

-

- Technical Expertise: Access to a team of experts with extensive knowledge in twin-screw extrusion technology and spare parts manufacturing.

- Customer-Focused Service: Dedicated support to address your needs and ensure complete satisfaction with our products and services.

Why Choose Finexpolymers?

At Finexpolymers, our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. With our advanced manufacturing capabilities and a team of skilled professionals, we deliver top-tier twin-screw extrusion spare parts that enhance the performance and reliability of your equipment. Trust us to provide the essential components that keep your extrusion processes running smoothly and efficiently.

Partner with Finexpolymers for all your twin-screw extrusion spare parts needs and experience the benefits of superior quality and service.